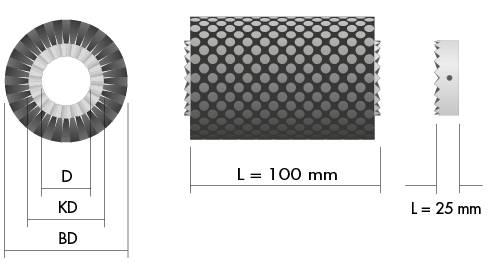

Quick Snap

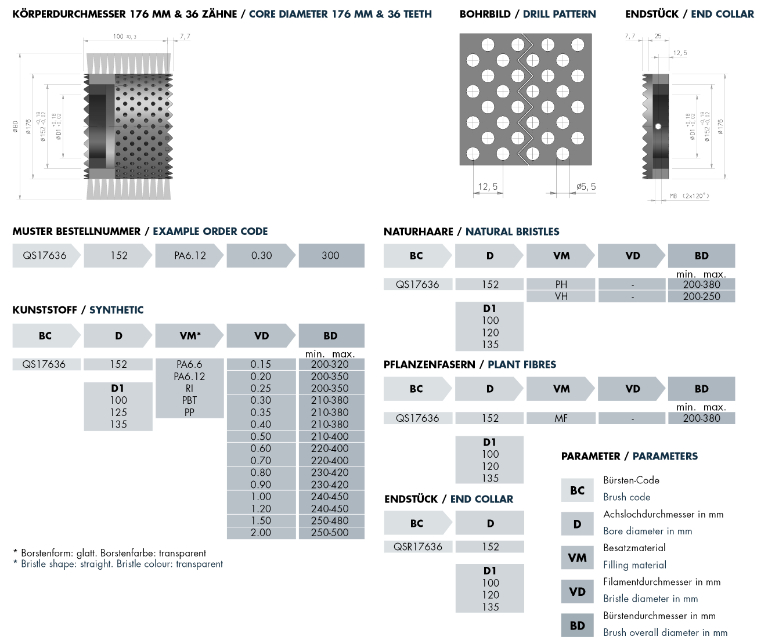

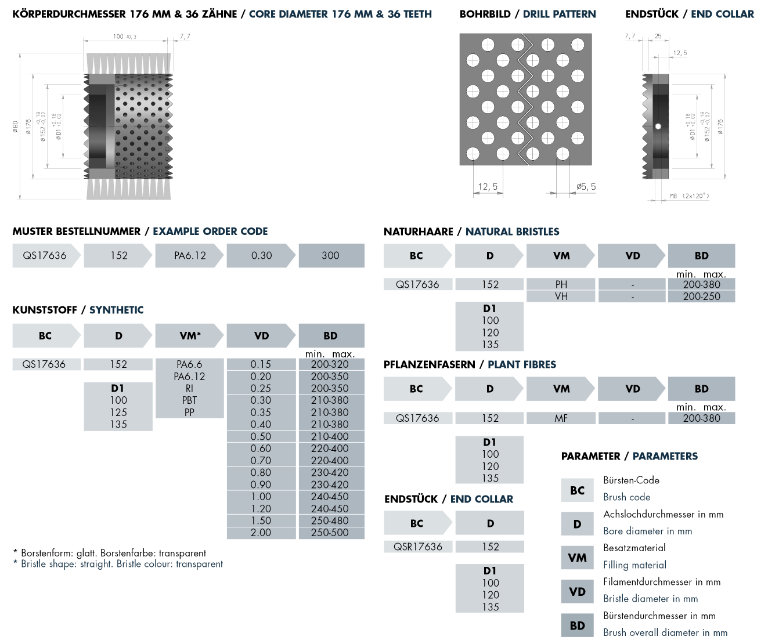

The Quick Snap system and its various components allow you to assemble your cylindrical brush/roller, creating a custom-made brush. With no need for complicated tools, you can assemble and disassemble used brush elements quickly and easily. This unique system can be used in a variety of applications, including washing, conveying, degreasing, powdering and sweeping. Users can replace the brush elements themselves with this system. The brush elements are brought together by the serrated ends. This results in a perfect brushing surface, with no residue left after brushing. The brushes have been developed for similar use from both left and right-hand sides. For this system, the various parameters are adapted to your needs: layout plan, dimensions, drilling diameters, trim, etc.

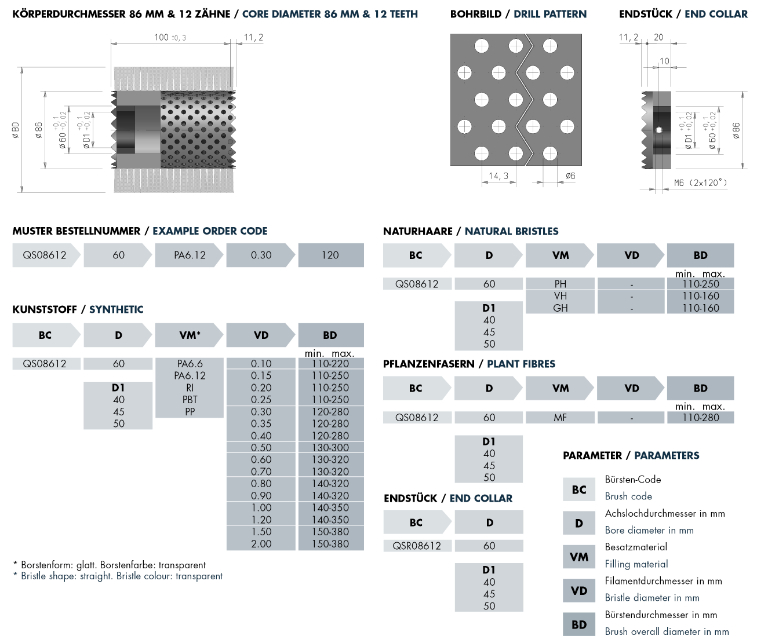

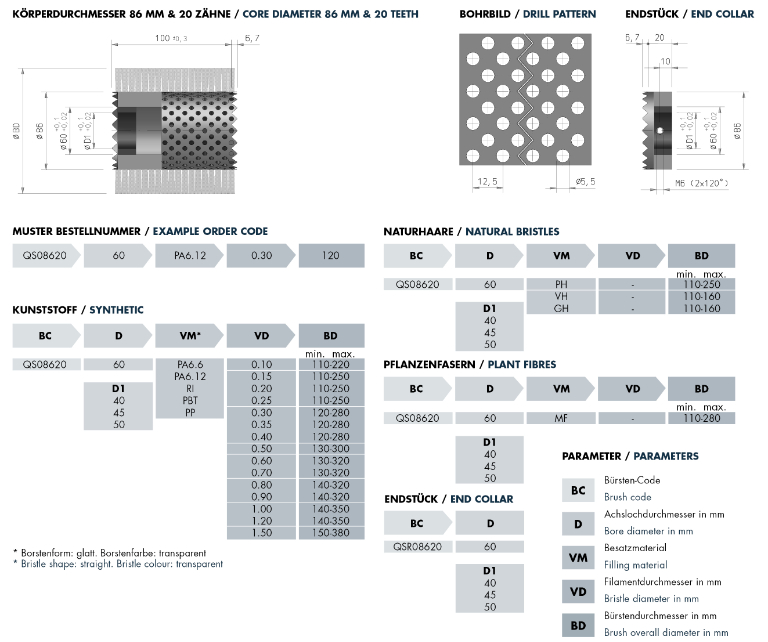

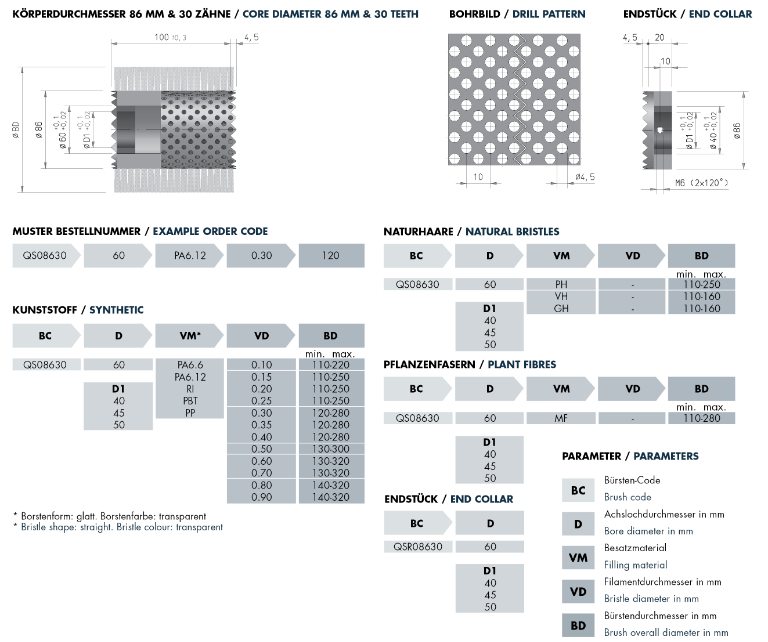

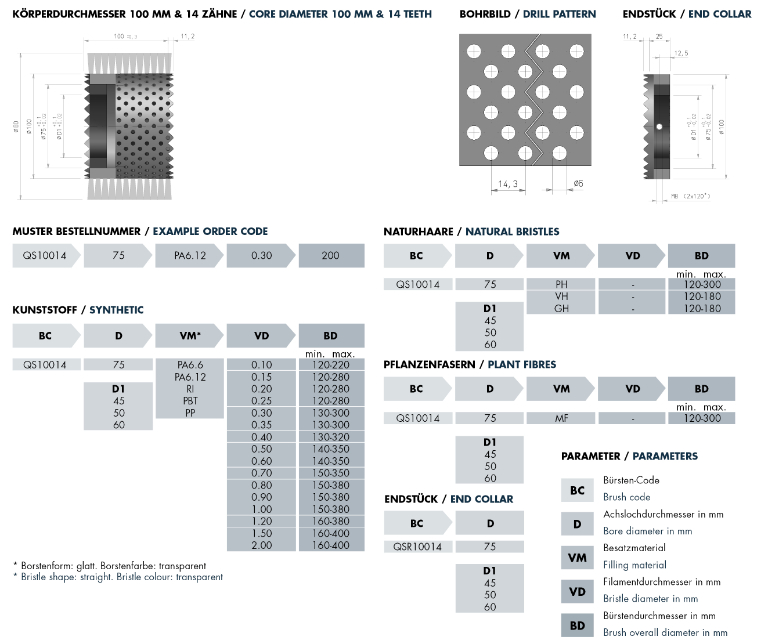

Models

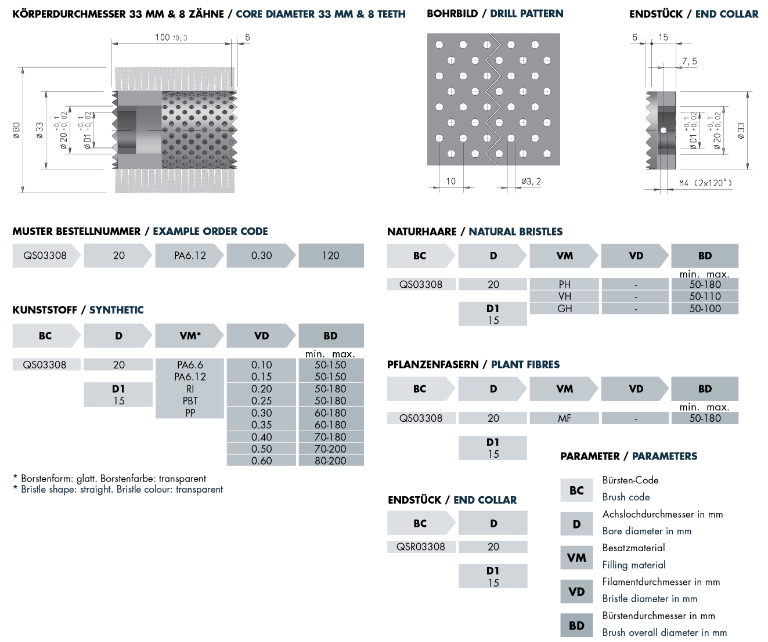

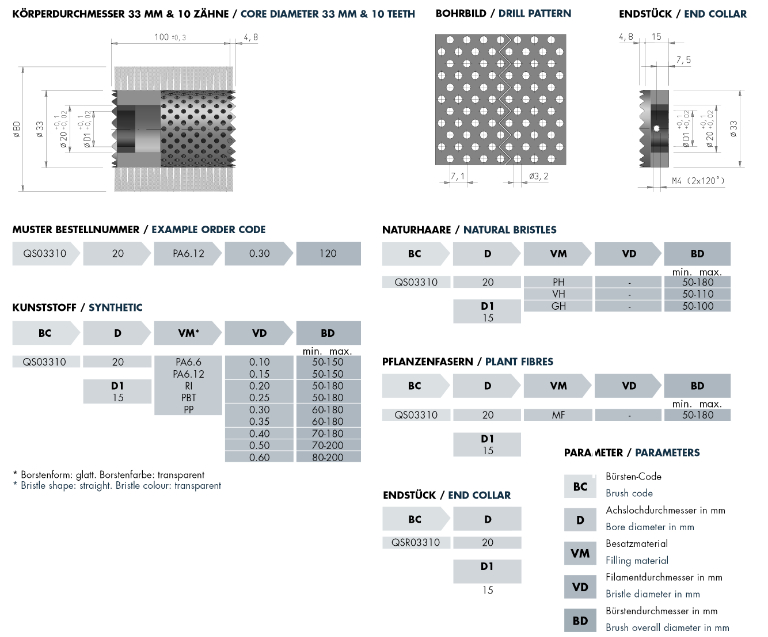

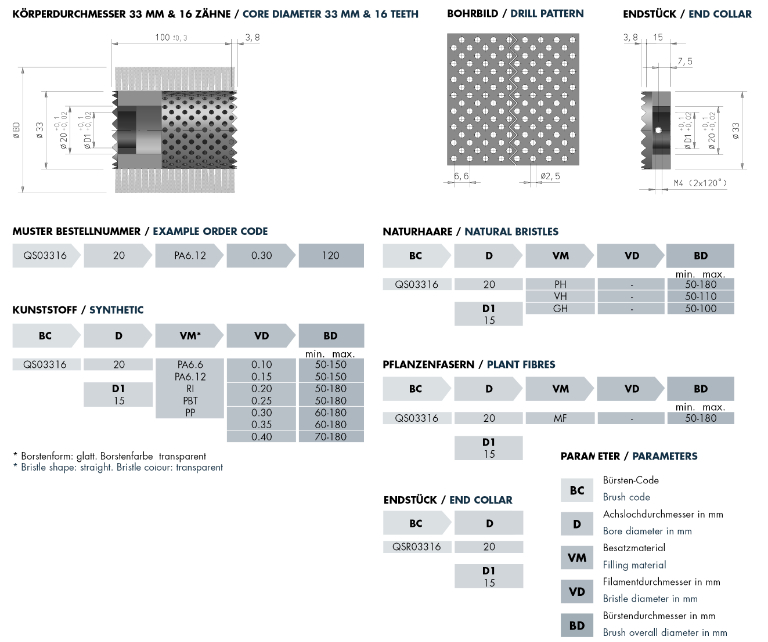

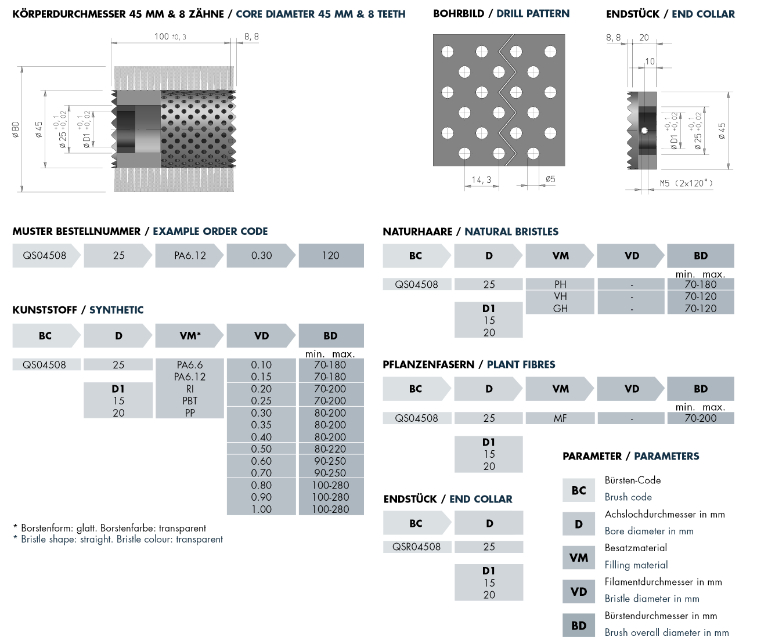

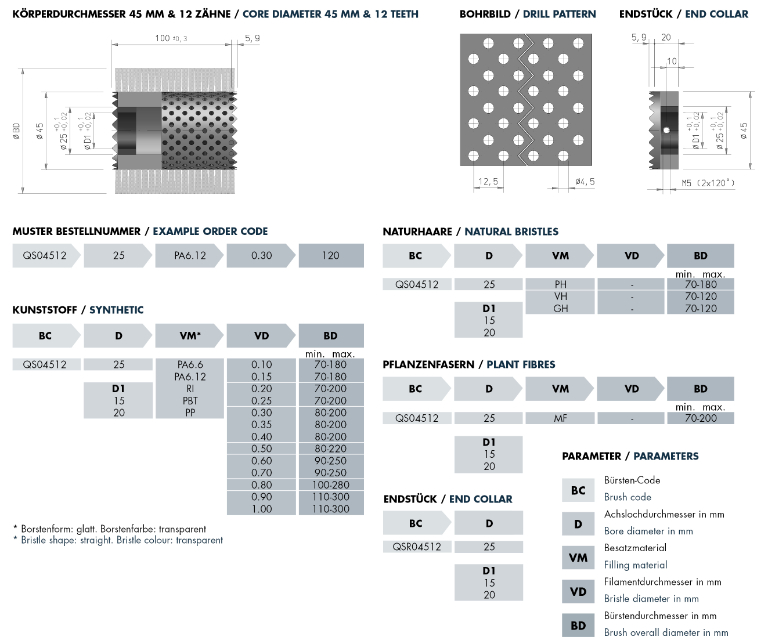

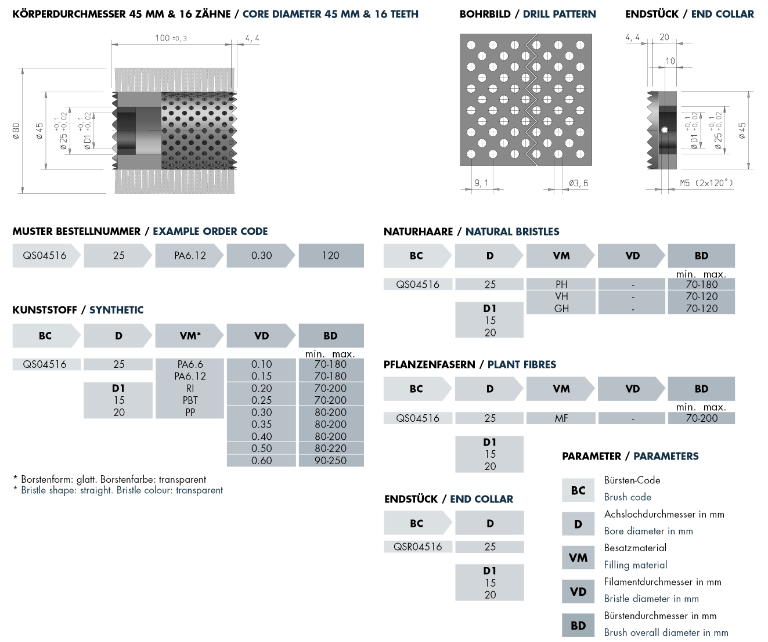

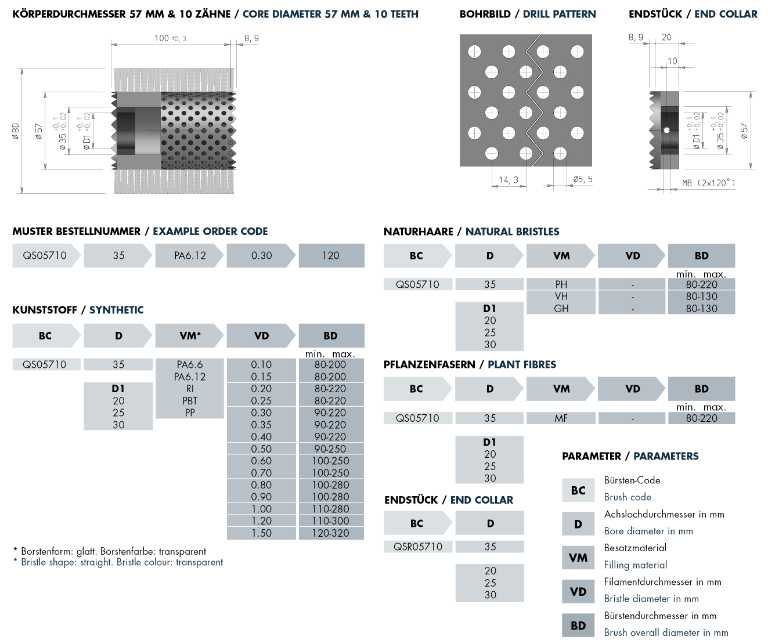

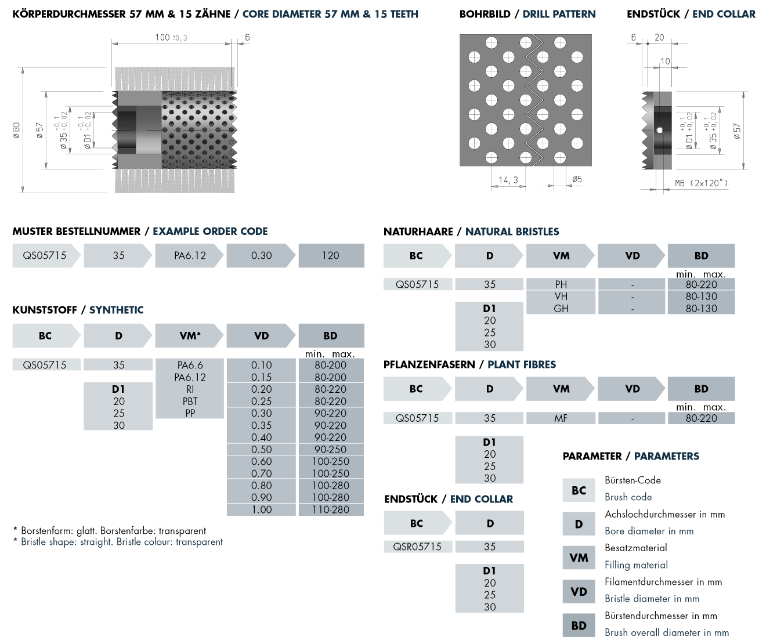

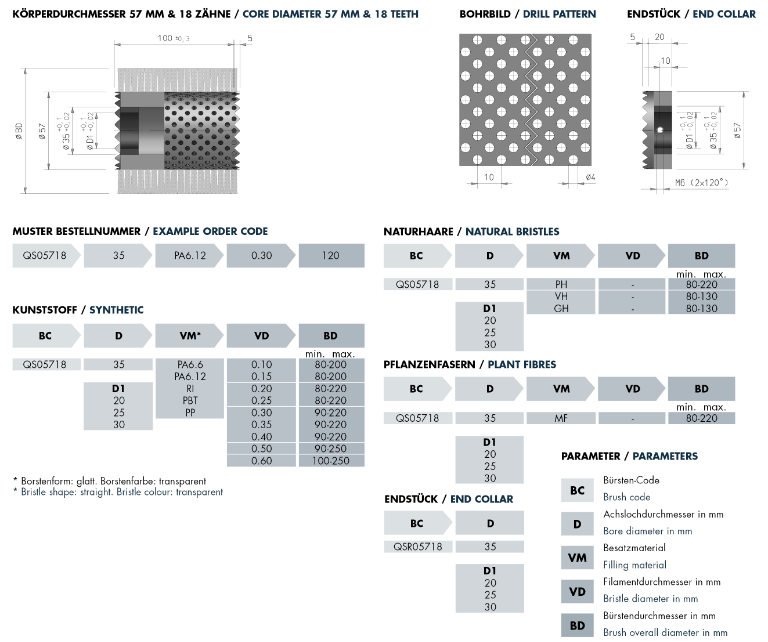

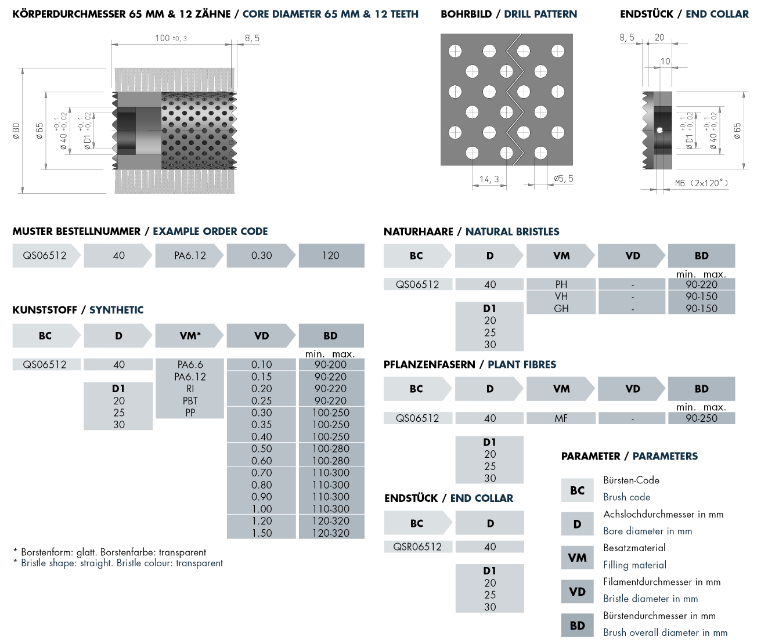

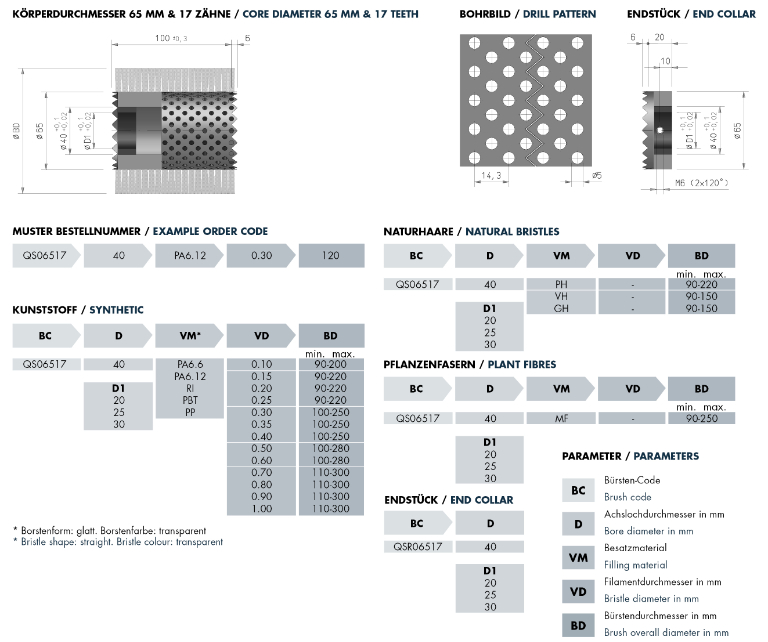

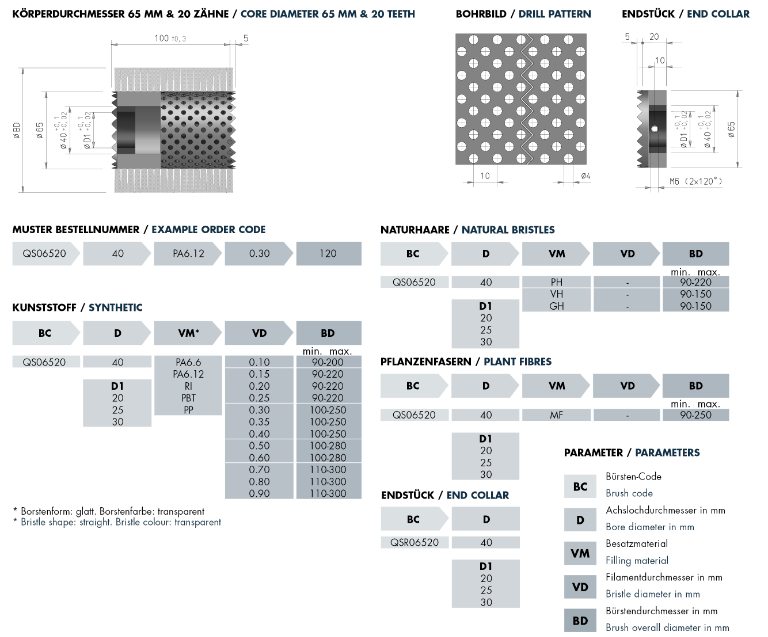

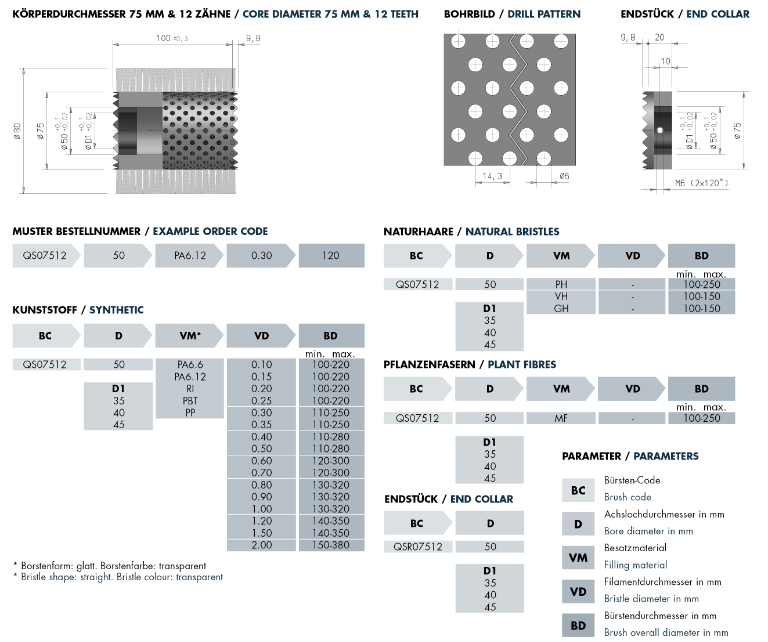

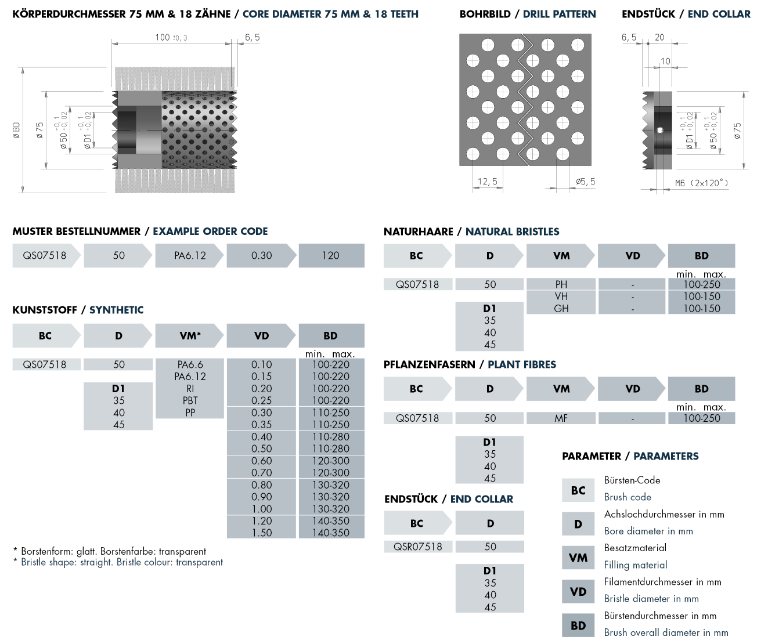

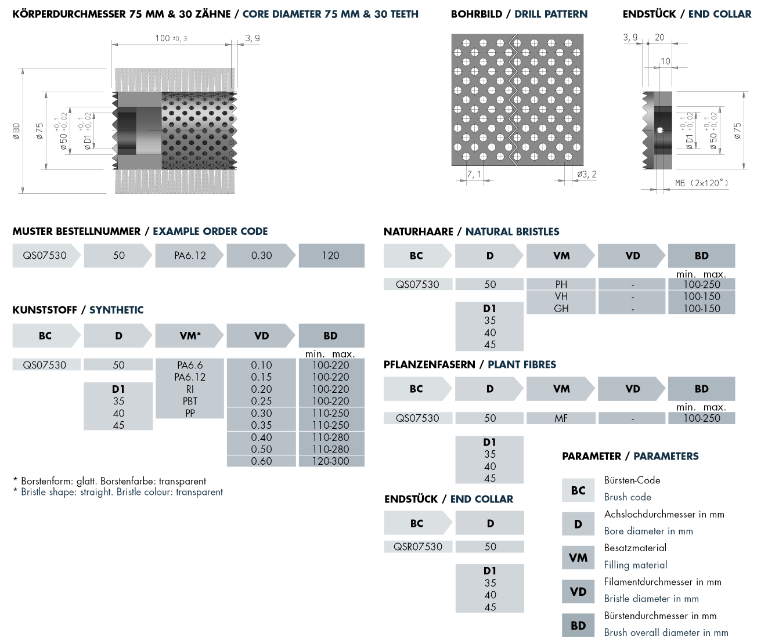

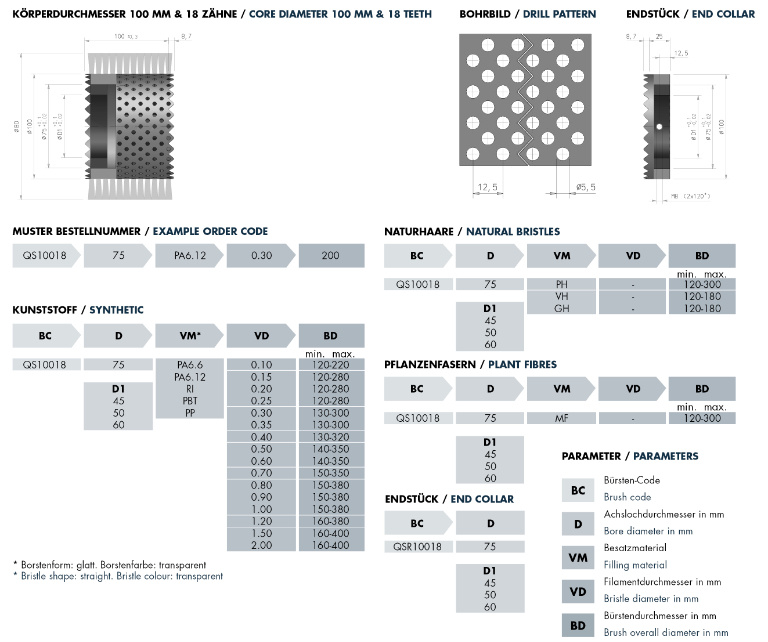

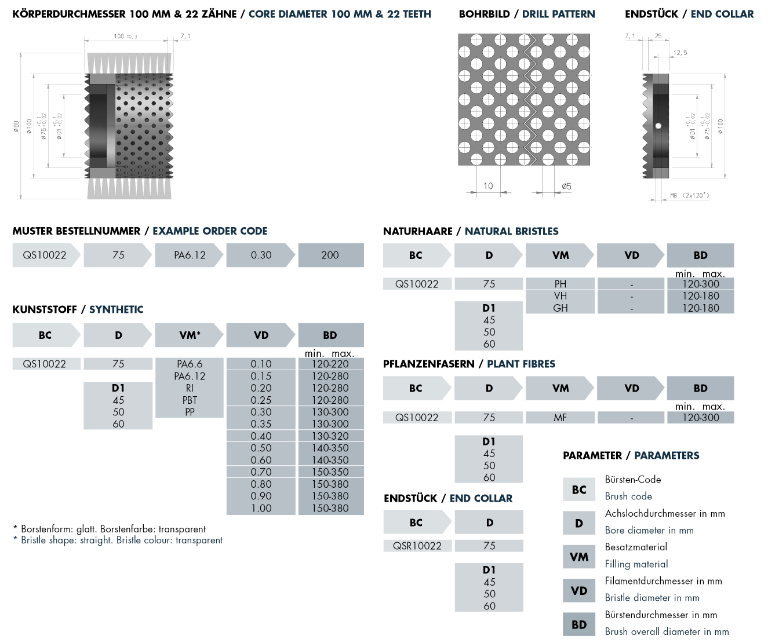

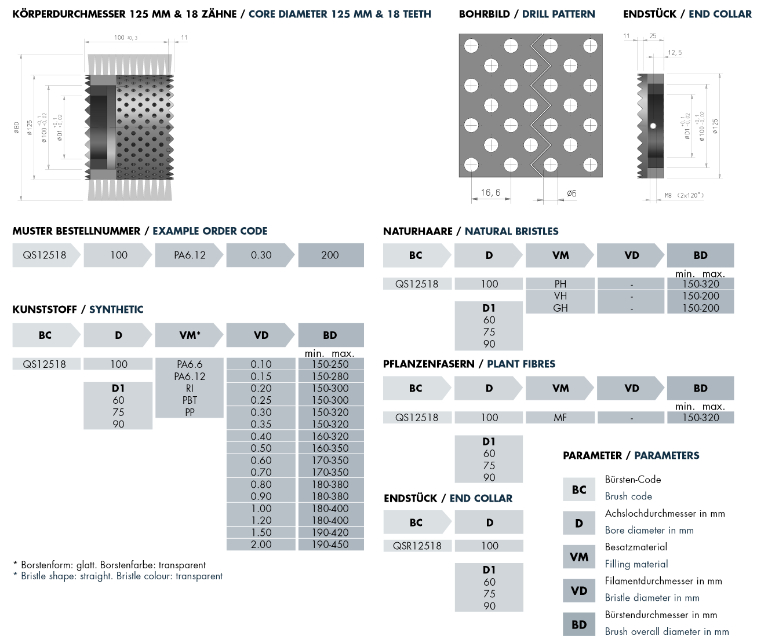

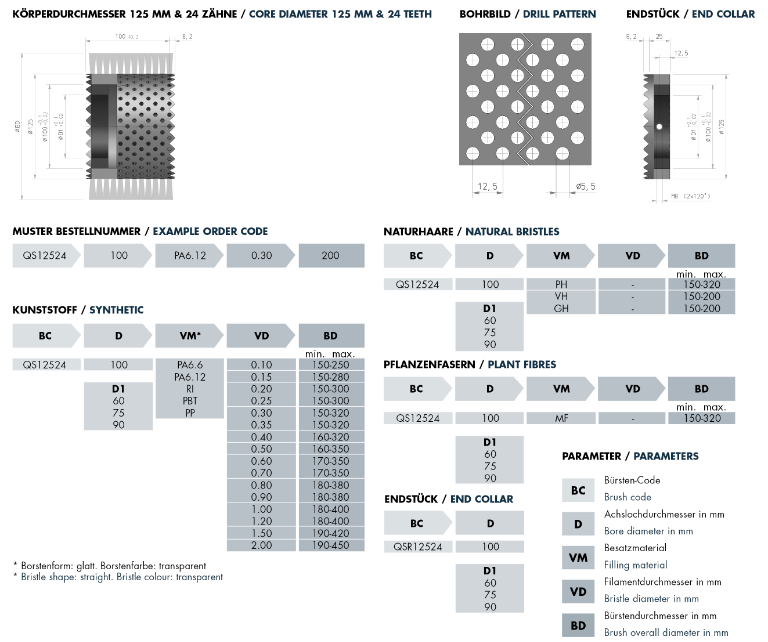

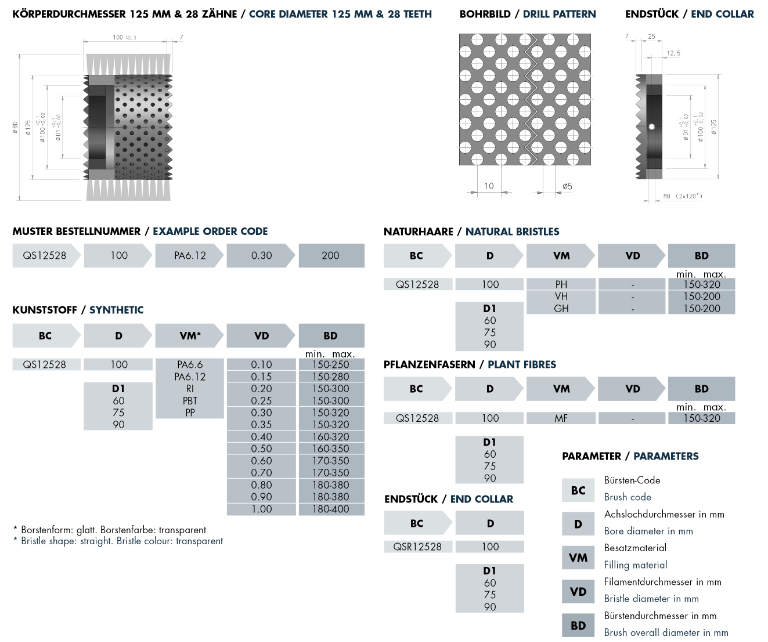

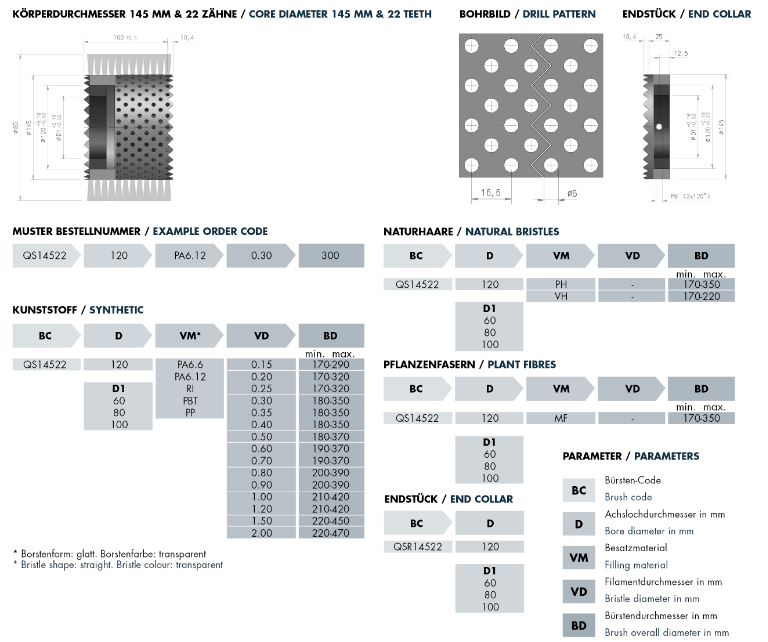

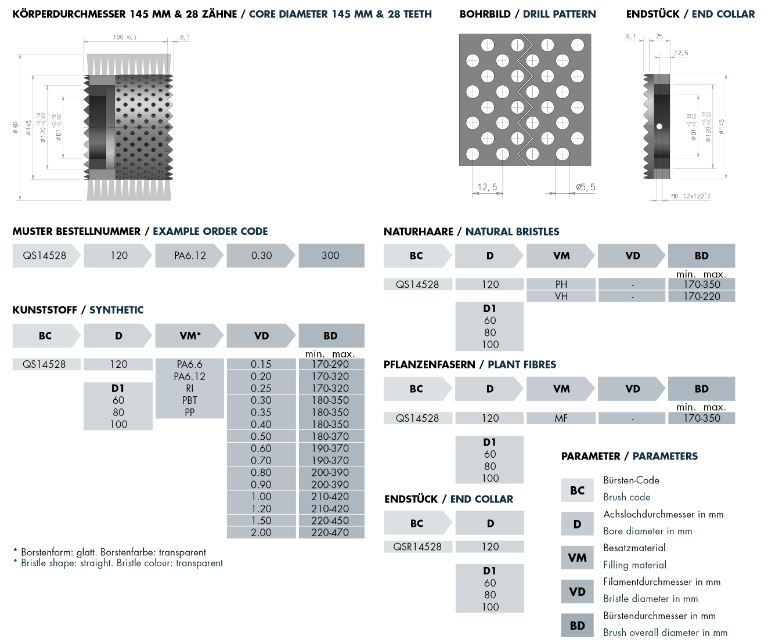

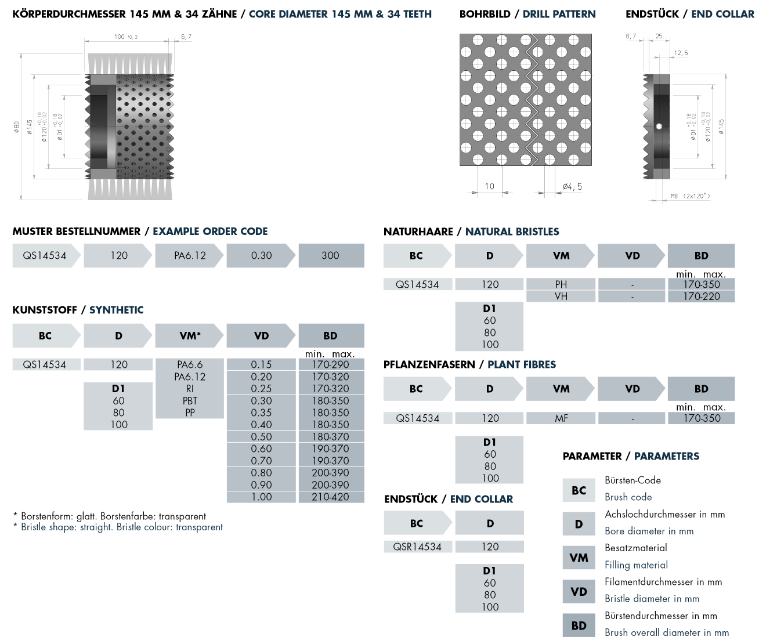

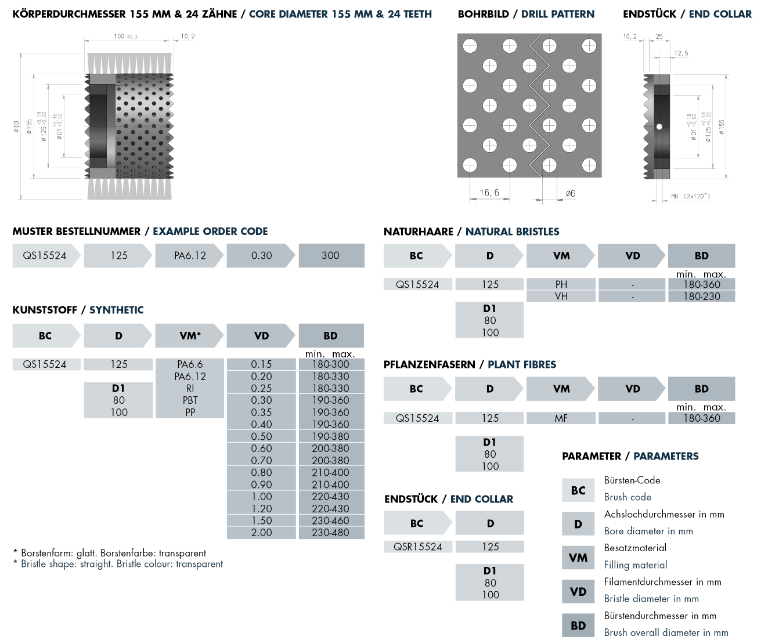

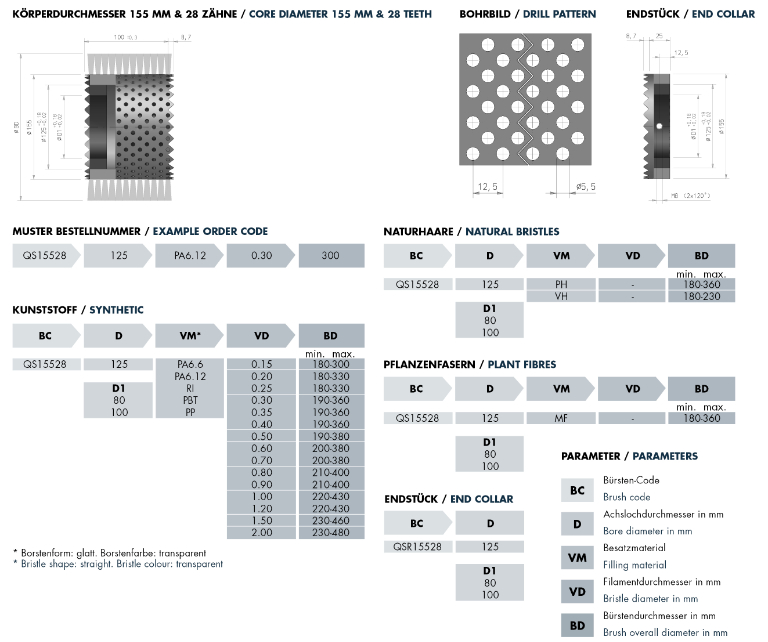

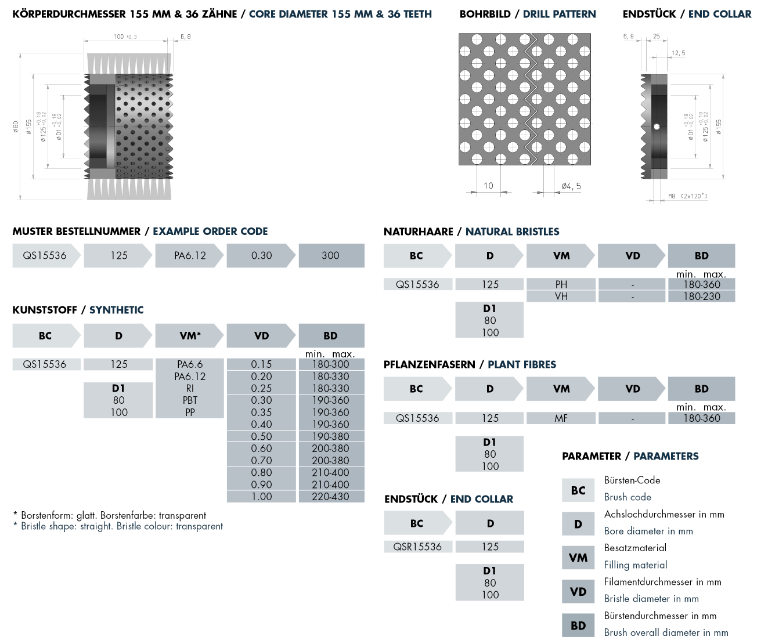

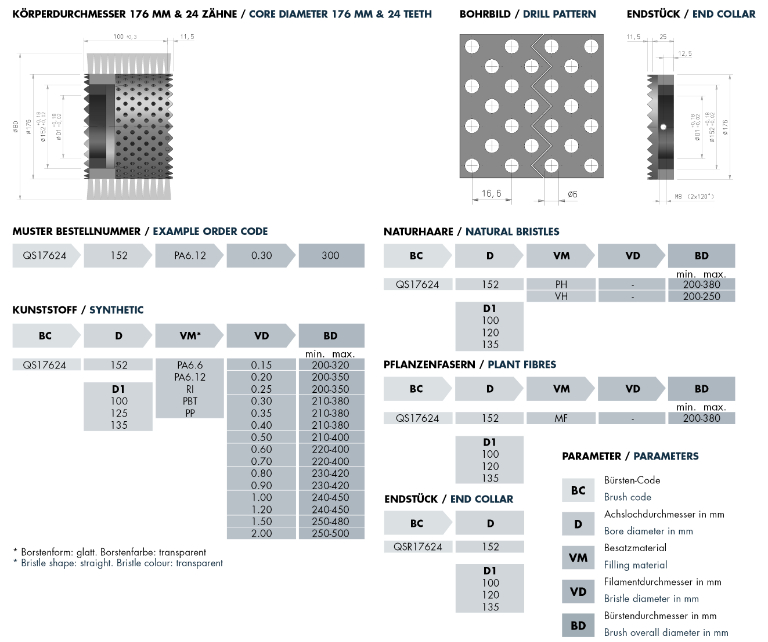

The models shown are standard. For all other requests, please contact our sales department.

Parameters

- KD – Body diameter

- D – Bore

- VM – Lining

- VD – Fiber diameter

- BD – Total brush diameter

- L – Length

- LE – Trainer length

| Quick Snap | |||

| Item number | Body diameter (mm) | Teeth | |

| QS03308 | 33 | 8 | |

| QS03310 | 33 | 10 | |

| QS03316 | 33 | 16 | |

| QS04508 | 45 | 8 | |

| QS04512 | 45 | 12 | |

| QS04516 | 45 | 16 | |

| QS05710 | 57 | 10 | |

| QS05715 | 57 | 15 | |

| QS05718 | 57 | 18 | |

| QS06512 | 65 | 12 | |

| QS06517 | 65 | 17 | |

| QS06520 | 65 | 20 | |

| QS07512 | 75 | 12 | |

| QS07518 | 75 | 18 | |

| QS07530 | 75 | 30 | |

| QS08612 | 86 | 12 | |

| QS08620 | 86 | 20 | |

| QS08630 | 86 | 30 | |

| QS10014 | 100 | 14 | |

| QS10018 | 100 | 18 | |

| QS10022 | 100 | 22 | |

| QS12518 | 125 | 18 | |

| QS12524 | 125 | 24 | |

| QS12528 | 125 | 28 | |

| QS14522 | 145 | 22 | |

| QS14528 | 145 | 28 | |

| QS14534 | 145 | 34 | |

| QS15524 | 155 | 24 | |

| QS15528 | 155 | 28 | |

| QS15536 | 155 | 34 | |

| QS17624 | 176 | 24 | |

| QS17636 | 176 | 36 | |

| QS17648 | 176 | 48 | |

Lining

The type of lining we use will depend on your application and industry. Do you have any questions about which fiber to use? Please do not hesitate to contact us.

| Lining | |||

| Abbreviation | Description | Benefits | |

| PA 6.6 | Polyamide 6.6 | Suitable for industrial applications, heat and abrasion resistant | |

| PA 6.12 | Polyamide 6.12 | Does not retain moisture, better resilience than nylon 6.6 | |

| RI | Rilsan | Does not retain moisture, very high wear resistance | |

| PBT | Polyester | Heat- and wear-resistant, non-retaining and certified for food use | |

| PP | Polypropylene | Non-moisture-holding, acid-resistant, lower abrasion resistance than nylon 6.6 and 6.12 | |

| PH | Horsehair | Flexible fiber for light (e.g. for plastic strips) | |

| VH | Pork silk | Harder than horsehair | |

| GH | Goat's hair | Extremely soft fiber for delicate work | |

| MF | Tampico fiber | Harder than hog silk (suitable for metal, for example, with the addition of a polishing paste) | |

Your success is our success

Need help finding

the perfect brush?

Do you have any questions about Quick Snap, or are you looking for a customized solution? Contact us, and we’ll be delighted to help.

Quick Snap

Please enter your requirements and contact details below. We’ll be happy to advise you on the best brushing solution for your needs.